Manufacturers used to focus on increasing efficiency and improving customer satisfaction in parallel a few years ago. Digital innovation, on the other hand, is radically changing the way manufacturers do business, forcing them to use new technology to drive change processes across the enterprise, including improving manufacturing performance, improving product quality, maximizing inventory, driving time-to-market, and meeting clients’ changing needs.

Dynamics 365 FO is a common option for manufacturers looking to improve end-to-end business process performance. It is now available as two separate applications: Dynamics 365 Finance and Dynamics 365 Supply Chain Management. It provides manufacturers with the convenience of unifying all facets of their supply chain using a single, comprehensive framework, thanks to features developed using deep analytics, embedded intelligence, and advanced reporting. Read on to find out what obstacles the manufacturing industry faces and how Dynamics 365 can help you overcome them quickly and accurately.

Manufacturers’ Present-Day Challenges:

Manufacturers are concerned about raising exposure while also increasing performance and lowering costs. It’s difficult to increase efficiency and profitability when maintaining high delivery deadlines and targets when you don’t have the right data at your fingertips. Manufacturers lack the visibility they need through functions such as finance, distribution, customer support, and supply chain operations due to the existence of siloed divisions and isolated legacy systems. The following are the most pressing issues confronting manufacturers today:

1. Operational visibility

Business excellence is driven by insight into the entire production process. Manufacturers, on the other hand, often fail to capture, incorporate, and envision global supply chain data and have little to no insight into end-to-end operations. Manufacturers would not be able to enhance coordination between manufacturing, supply, service, and sales unless they have easy data access to supply chain data. Weak cross-departmental coordination and alignment of various business processes result in a lack of understanding of company-wide output metrics.

2. Employee Empowerment

Empowering workers are among the first steps in creating a great manufacturing enterprise, as the global workforce becomes more demanding in terms of the interactions they enjoy at work. However, in a dynamic manufacturing environment where each job operates in isolation with department-specific tools and systems, supplying the workers with the right tools and data has a significant effect on daily task productivity and performance. Employees struggle to keep up with the speed of manufacturing without access to role-specific equipment or a 360-degree view of the market, depending on error-prone, time-consuming mechanical tasks to complete day-to-day tasks.

3. Productivity Enhancement

Productivity is about adding value to everything you do, not just doing more. Getting a streamlined view of the process and connectivity to smartphone and virtual reality platforms to track and fix problems remotely boosts manufacturing efficiency. However, efficiency gains would be impossible to achieve if the workforce is unable to intelligently organize activities between different roles. Employees are unable to prioritize workloads, produce tailored reports, or access appropriate data due to a lack of intelligent resources, resulting in low productivity and expensive engagements.

4. Field Service Management

In a field service industry where employees spend the majority of their time on the job, using strategies and workflows that are tailored to particular business requirements aids in delivering the right product to the right field service agent at the right time. Ground officers, on the other hand, find it difficult to standardize workflows, cater to clients, and obtain timely approvals in the lack of appropriate field service capabilities. Agents also have trouble managing resource assignments through various task orders, and companies fail to allocate the right field service person with the appropriate job skills to the right place at the right time, causing issues to arise. Due to a lack of real-time updates and customized communications, transparency and an accurate view of the purchasing cycle are further hampered, making it difficult to ensure procurement stays within the defined quantity and price ranges.

5. Customize Customer Service

Providing consumers with more exposure and confidence through customized customer support is critical for every manufacturing company to succeed. However, without intelligent analytics in place, providing value-added customer service across the self-service, group, or social media requires the workforce to manually monitor customer interactions across all touchpoints in order to provide smooth and reliable omnichannel experiences. Employees must be on their toes 24 hours a day, seven days a week in such manual methods, and they cannot take time off to concentrate on high-value experiences. Employees often fail to provide a 360-degree view of and customer’s path in the absence of structured workflows, making it challenging to predict needs, personalize experiences, and provide value at any touchpoint.

The Effect of Dynamics 365 on the Manufacturing Industry:

Microsoft Dynamics 365 bridges the gap between siloed business systems for manufacturers, providing a wealth of capabilities in analytics, embedded intelligence, and automation, as well as the comfort consumers demand from modern technology. It links every part of the manufacturing supply chain with a single, end-to-end framework that aids inefficient business management at the right pace and scale for that organization.

Manufacturers may use Dynamics 365 to optimize processes around the supply chain while still setting the groundwork for potential technology integration. Here are some examples of how Dynamics 365 has improved production processes:

1. Collaboration and visibility

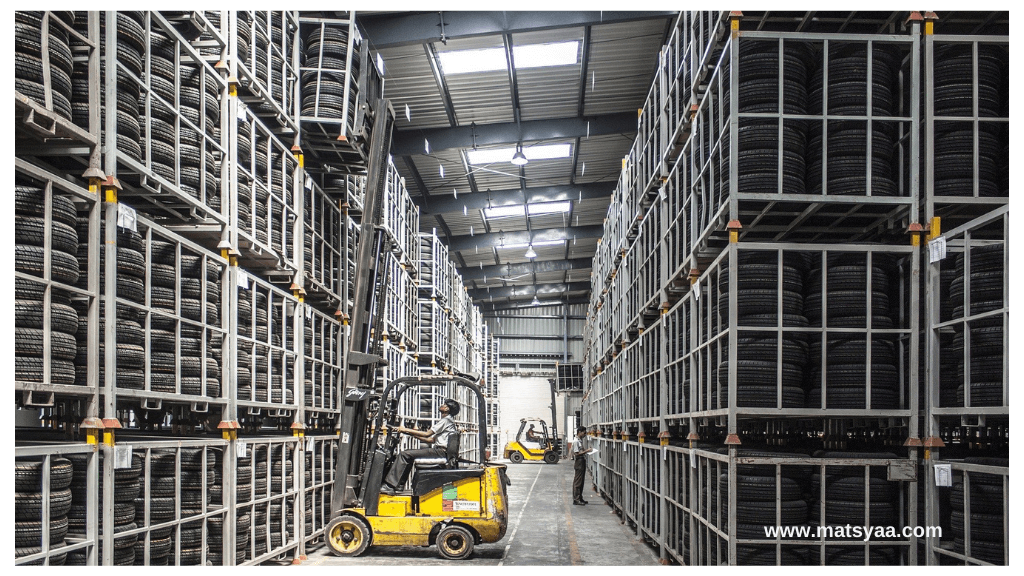

To provide transparency and management across the supply chain, Dynamics 365 combines distribution and buying processes with logistics, manufacturing, and warehouse management. The inter-company and multi-site skills make it easier to handle dispersed enterprises and streamline vendor collaboration. Manufacturers can use Dynamics 365 to:

- Sync logistics through locations, warehouses, and modes of transportation to improve fulfillment and cut costs, and modernize company logistics.

- Using predictive analytics, obtain oversight across all platforms and warehouses, and react proactively to issues.

- Streamline procedures, cut procurement costs, and gain more flexibility by automating procure-to-pay processes.

- Obtain greater insight into operations from output to sales by collecting, integrating, and visualizing global supply chain data.

2. Productivity and Efficiency of Employees

Empowering workers is critical in the manufacturing industry for increasing output growth. Dynamics 365 provides workers with everything they need to complete assignments easily and effectively, thanks to its intelligent machine learning, coordination, and analytics capabilities. Employees will only provide personalized support and advice to customers and transform relationships into sales if they are motivated. Manufacturers can use Dynamics 365 to:

Collect and analyze data from linked products and equipment, and give workers more freedom to collaborate.

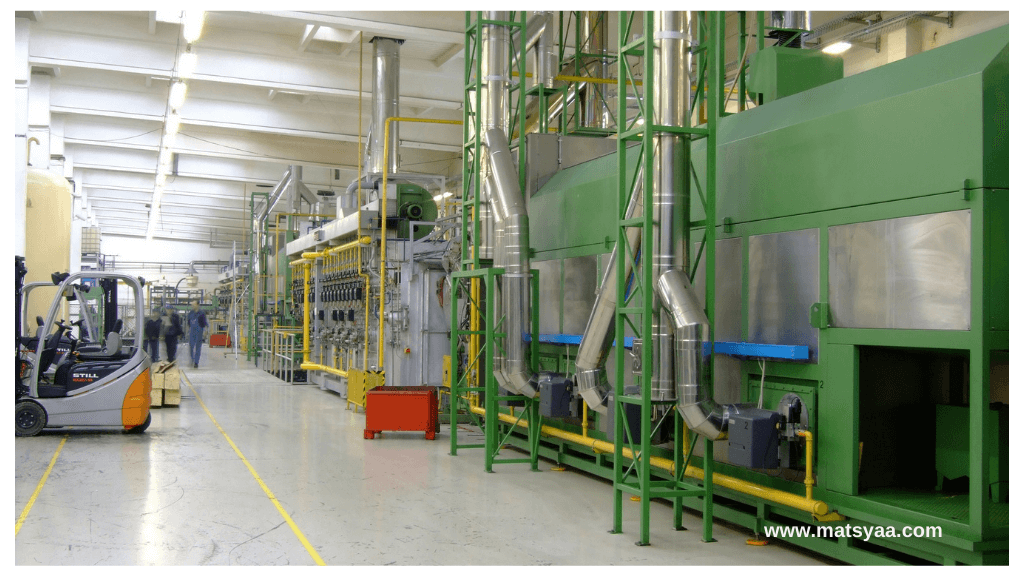

Automate processes throughout the manufacturing lifecycle to increase productivity and improve the innovation cycle.

Employees would have a greater understanding of consumers and their needs if they have a 360-degree insight into customer assets and job orders.

Enable machine learning algorithms to provide instant feedback for productive troubleshooting and maintenance.

3. Customer Service and Interaction

Optimizing manufacturing efficiency and rising customer loyalty were once thought to be two different goals. Organizations are now looking to communicate with the always-connected consumer through creative means such as social networks, as digitization has removed the limits of space and time. Manufacturers can use Dynamics 365 to:

- Transform the way business is done by adopting a client-centric approach while optimizing operations.

- Customers can be involved in the product life cycle, from production design to field support.

- Offer a variety of value-added services to go along with the product sales, resulting in additional revenue opportunities and stronger customer relationships.

- Create and offer customized content that consumers can access from anywhere and at any time.

4. Insights in Real-Time

With insight into business activities being the single most critical aspect for better decision-making, Dynamics 365 provides real-time insights on almost any platform, at any time, thanks to its built-in analytics. The unmatched, rapid and scalable deployment options offer the best of both worlds (cloud and on-premises) to meet global business requirements of today and have the flexibility and ease to change as business needs evolve over time. Manufacturers can use Dynamics 365 to:

By combining existing legacy processes and scaling internationally at their own speed, you can streamline and automate business process improvements.

By remotely tracking and addressing problems, you can achieve a complete overview to integrate process oversight and institutionalize productivity gains.

Improve service efficiency and margins by supplementing break-fix assistance with remote control and proactive maintenance services.

Equip technicians with smartphone and digital reality tools that leverage existing knowledge and reduce costly engagements to enable intelligent teamwork between technicians.

Improved Outcomes in a Unified System:

Business leaders in every industry have realized that customer loyalty is the most important factor in every company’s success. To remain competitive, companies who want to develop customer-centric strategies are focused on revamping the value for customers and improving their operating procedures. Businesses have often seen emerging info and digital technology in terms of what it could do for them, such as increase profitability and consumer reach by implementing new business models. The digitization of manufacturing necessitates a change in the way businesses work – from a siloed approach to a much more organized, linked one – with consumers having a variety of new options and making decisions on what to concentrate on or purchase across multiple channels.

To stay competitive in the modern manufacturing age, companies must operate faster and smarter. Microsoft Dynamics 365 bridges the gap across CRM and ERP systems, providing manufacturers with the resources they need to boost productivity and deliver better products faster. It supplements required skills with rich analytics, embedded intelligence, and the comfort people expect from user apps on their phone or tablet by uniting many aspects across the manufacturing lifecycle. Since digital transformation does not happen immediately, a cohesive system like Dynamics 365 can be an important component in achieving better results. Manufacturers can enhance project management, gain insight into operations, inspire staff, increase business efficiency, and provide personalized service by enabling robust project management.

Want to explore how Microsoft Dynamics 365 can support your digital sales? Talk to our Technical Team.